NHI Headlines

Success of Mixed Ownership Reform of the Old State-owned Enterprise: Technical Innovation Entering the “Fast track”

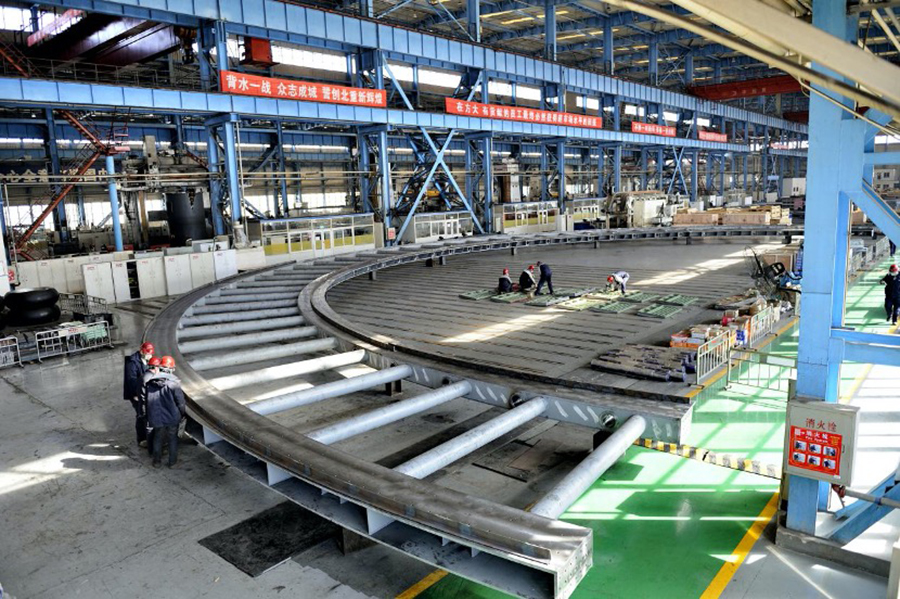

Relying on the new mechanism and management mode, Northern Heavy Industries Group Co., Ltd (NHI) under Fangda Group has been keeping on innovating and developing so as to create new competitive advantages after mixed ownership reform. Within one year, NHI has completed the technical updating of 4 traditional products such as 550mm2 belt sintering machine as well as development design of 10 new products such as HLS-425 new type sinter annular cooler. The development of new technology and products has entered the “fast track” at all rounds.

Technical Innovation Activated by Mixed Ownership Reform

On April 30th, 2019, NHI successfully completed the judicial reorganization and Liaoning Fangda Group became the largest shareholder of NHI by laws. After carrying out mixed ownership reform, Fangda Group, the strategic investor, has brought NHI the modern enterprise system, management mode, abundant capital, market resource support and brand new enterprise culture, which makes NHI promptly form the market-oriented structure and operation mechanism. With the full support from Fangda Group, NHI promptly integrated the advantages in technical resources, adjusted the products structures, implemented the products updating, and fully improved the core competitiveness in the segment market, activated the market capabilities to survive and develop.

During the process of speeding up the product technical updating of traditional products and quickly bringing the updated products to the market, NHI continued to increase investments in design and development of new products. 13.65 million yuan was invested to change graphic workstations and servers, to purchase 254 computers and to update 9 design softwares, which greatly improved the design and development conditions.

By completing the system and strengthening incentives of the design optimization, the product design schemes were optimized in each aspect. In one pipe conveyor project in Inner Mongolia, the user specified the brand and model of electrical components in the technical agreement. The design department of NHI had a deep communication with the design institute, and made a detailed survey on the supply power and DCS system of the whole project. With the full analysis and comprehensive study, NHI proposed an optimized scheme of using the high-voltage system designed by this institute, directly connecting with the high-voltage system supplied by NHI without increase of the cost. Through several effective negotiations between the owner and design institute, the optimized scheme was finally agreed and an important minutes of meeting was signed. According to calculation, the cost of electric control system for this project decreased by 914500 yuan, with a cost reduction rate of 19.91%. In February this year, NHI completed five cost reduction projects through optimizing the design scheme, achieving a cost reduction of 1.396 million yuan, with a cost reduction rate of 15.23%. In March this year, NHI completed two projects, with a maximum cost reduction rate of 21.06%. By optimizing the design scheme, the cost can be reduced and efficiency can be increased from the start of product manufacturing, which not only reflects the technical strength of NHI, but also constantly creates greater value for customers.

Continuing Updating in Traditional Products, and Speeding up in New Product Research and Development

In march this year, Mr. Chen Qinliang, chief engineer of coal mine engineering technology company, with his project team, successfully designed, developed and manufactured the T12 active multi-functional crawler scraper with full independent intellectual property rights after 10 months of hard work, which not only broke the monopoly of European and American countries, but also filled a gap in the field of national construction machinery.

“As long as closely following the market demands, customer-centered and speeding up technical upgrading and innovation of products, NHI can stand firmly in the fierce market competition.” Said by Mr. Yang Tao, the assistant president of NHI.

As a major leader in the global full section TBM industry, NHI has independent intellectual property rights and patent technology for various types of products, and has accumulated rich experiences in developing and manufacturing different types of full section TBMs. In line with the market developing demand, NHI completed the technical transformation and upgrading of two 6.48-meter-diameter earth pressure balanced TBM for the South extension line project of Shenyang Metro Line 2, which further established the leading position of NHI in TBM market.

At the same time, the first new TBM of φ 4.5m full section Half Coal Rock designed and developed by NHI has completed factory acceptance. The introduction of the full section TBM into the coal tunnel construction in the half coal and half rock strata, with the monthly advance of over 600m, is undoubtedly a breakthrough in the construction of mining roadways, which not only solves the current geological adaptability problem that the traditional open or double shield TBM cannot be used in the half coal and rock strata , but also expands the application scope of TBM in the coal mine roadways construction.

At present, the new products such as HLS-415 sinter annular cooler, 1000t/h aggregate production line, etc., have become important supports for new economic growth points of NHI, which is of great beneficial to the society and economy.

Using Technical Innovation Advantages, Improving Market Competitiveness

With full confidence, higher goal and requirement, the reloaded NHI is continuously increasing investment in technology research and development, mobilizing the enthusiasm of the majority of scientific research and technical personnel, making full use of relocation and transformation projects in steel industries, accelerating the process of new product design and development, and rapidly creating new economic growth points. On basis of national environmental protection, combined with the development trend of iron & steel, cement and other industries, NHI will start the product research and development in the new field of environmental protection and dust removal. Relying on the aggregate engineering project, NHI will implement the engineering technology development, and quickly form a complete set of engineering technology capacity. By accelerating the standardization, modularization and parameterization design and R&D of general components, NHI will improve the design efficiency, shorten the technical preparation cycle, and improve the profitability of products. At the same time, NHI will accelerate the technological upgrading and transformation of traditional products, through the whole process management and control of product design quality and design cost, rapidly promote the upgraded products to the market, formulate the design cost reduction plan for the project product design. Modern technical means and value engineering methods will be employed to increase the product optimization and cost reduction. The improved performance and quality of the products, the decreased costs and upgraded market competitiveness will provide strong supports for NHI to fully explore the market and improve the quality of operation.